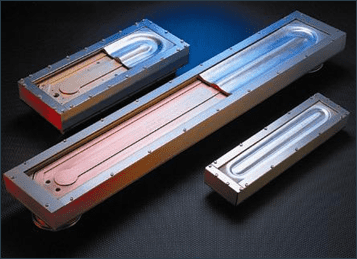

RECTANGULAR CATHODES

With target widths of 2″ to 11″ and lengths up to 140″, you can get Sierra’s rectangular cathodes in virtually any size you’re likely to need. As with our round cathodes, you can choose from several different mounting styles and add the process gas manifold.

With target widths of 2″ to 11″ and lengths up to 140″, you can get Sierra’s rectangular cathodes in virtually any size you’re likely to need. As with our round cathodes, you can choose from several different mounting styles and add the process gas manifold.

Target Utilization

Target utilization and life are two important factors in choosing a magnetron cathode. The table below shows typical target erosion results for many of our cathode designs. We base our measurements on “useable” target utilization and on standard “burn-through” target utilization. However, the best way to verify the utilization of a target is to look at the used targets.

| Target Size | % Used ** A / B |

KWHR | Volume Used | Groove Depth |

| 2 x 38 x 1/4 3.5 x 30 x 3/8 5 x 12 x 1/2 5 x 12 x 5/8 5 x 36 x 1/2 6 x 12 x 5/8 6 x 46 x 5/8 8 x 36 x 7/8 |

28 / 33 40 / 43 38 / 42 33 / 39 37 / 40 41 / 48 40 / 47 44 / 50 |

181 395 371 409 975 793 2170 3361 |

5.1 in3 15.7 in3 12.0 in3 15.0 in3 36.0 in3 23.0 in3 69.0 in3 111.0 in3 |

0.183 0.250 0.450 0.525 0.461 0.575 0.583 0.763 |

Results are for aluminum targets, most eroded at 3 mTorr Argon at 9KW.

**We use two methods to calculate target utilization: Method A: % weight lost. Method B: % weight lost * target thickness / groove depth. Method A is useful for processes that use targets without backing plates, while method B is used when a backing plate is present, allowing erosion through the full target thickness.